Check out our fabricated densified fiber solutions. A diverse product that branches into many catagories. From furniture and bedding to cold chain, speak to a rep today and see how densified fiber could be a solution for you

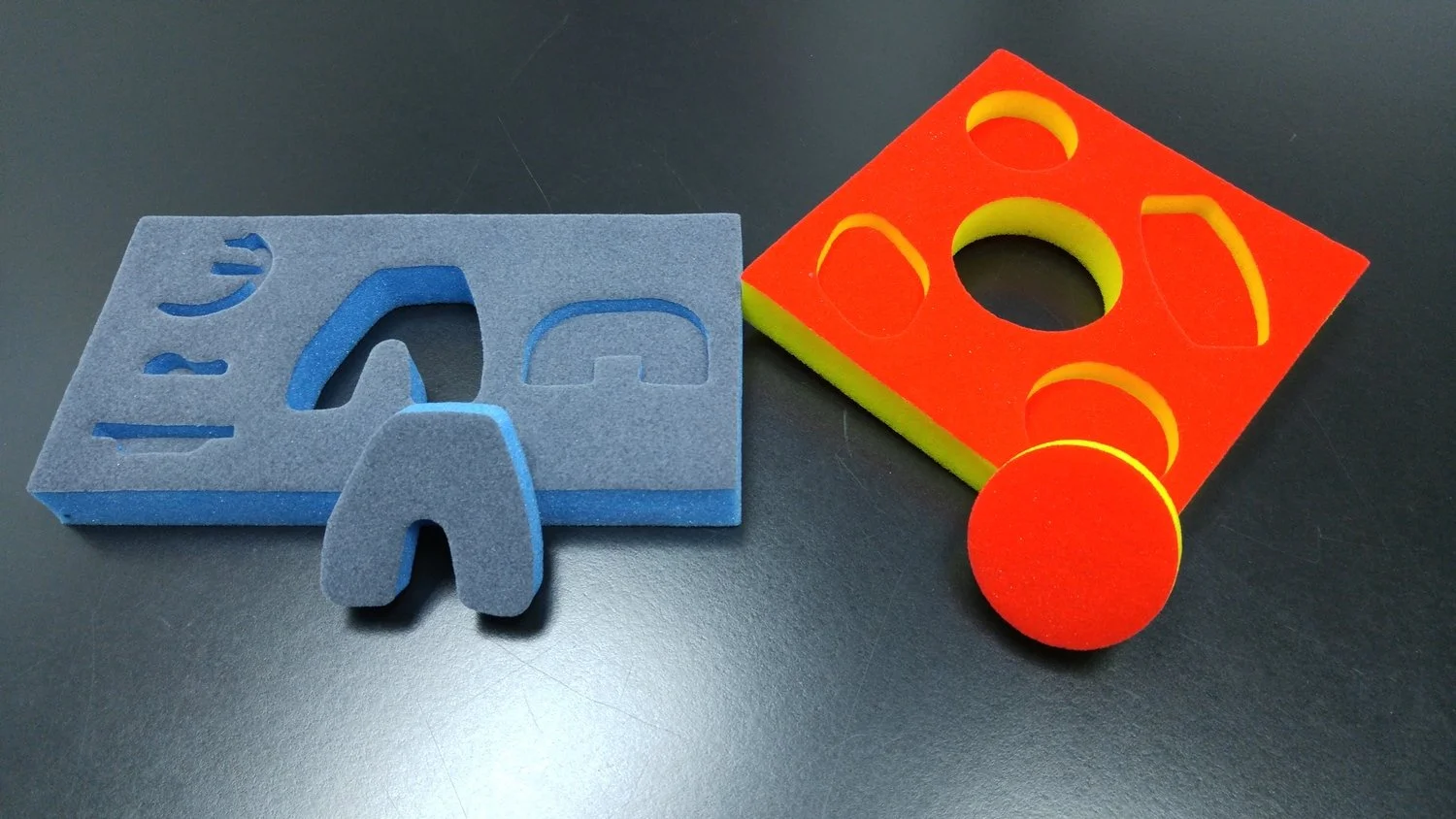

Adams Packaging has both high tonnage flat bed die cutting and extra wide media cutting. Contact a sales person for more information and cutting solutions.

A closed-cell polyethylene (PE) plank foam that is easy to fabricate that is resilient and non-abrasive...

Chemically cross-linked polyethylene (XLPE) foam is a durable closed-cell material featuring a smooth...

Foam-in-place systems provide versatile protection by molding cushions around products and shielding them from impact...

Product Details. A closed-cell polyethylene (PE) plank foam that is easy to fabricate that is resilient and non-abrasive...

Polyurethane is a foam used in many indusutries including furniture, bedding, seating, automotive, packaging...

About Adams Packaging

Founded in 2024 by packaging industry veteran Jeff Gold

Based in Fort Wayne, Indiana, serving the Great Lakes region and beyond

Emphasis on understanding client needs and customizing protective packaging

Commitment to open communication, reliability, and exceeding expectations

With an unwavering dedication to customer service and satisfaction, Adams Packaging strives to go the extra mile and ensure product safety and performance

Skive plank / bun materials up to 50” wide. Sheet and plank thickness tolerances are 1/8”. Please talk to a member of our sales team to find out more